armstrong

hydraulic cylinders

Hydraulic Ram Repair and Hydraulic Cylinder Repairs Service

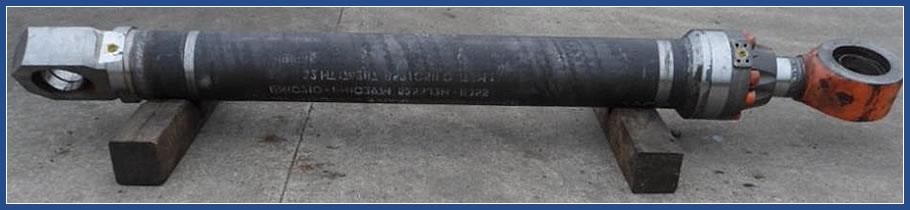

If you need a hydraulic ram repair, we have the expertise and specialist equipment in our fully equipped engineering workshop using CNC, CAD and CAM. We are experts in quickly identifying the problem and repairing hydraulic rams.

Our equipment is able to handle the Large Bore Hydraulic rams and long stroke rams for many different types of machinery.

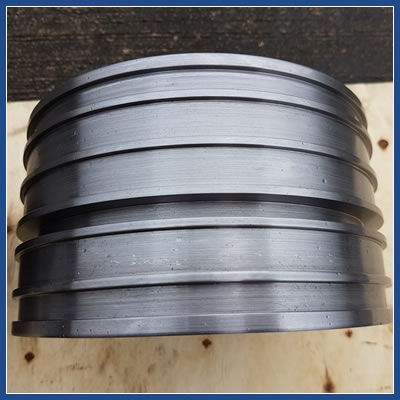

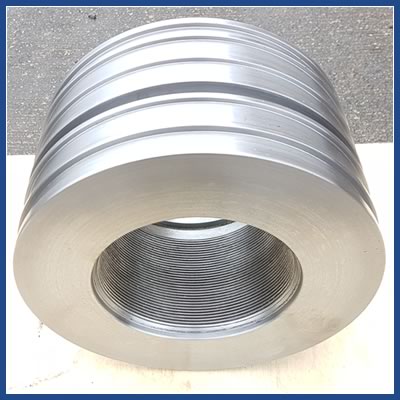

We stock a wide variety of replacement hydraulic ram parts and materials and have the machinery to manufacture any replacement part. All our materials are of the highest quality and we only use induction hardened chrome bar for the most demanding hydraulic rams, such as quarry and excavation machinery.

Types of Hydraulic Ram Repairs we handle:-

- Dented or scored hydraulic rams

- Bent rod and scored rams

- Leaking hydraulic seals

- Rusting or pitted chrome

- Damaged / split rod ends

- Long Stroke hydraulic ram repairs up to 9 meters in length

- Wide cylinder ram repairs up to 600 mm

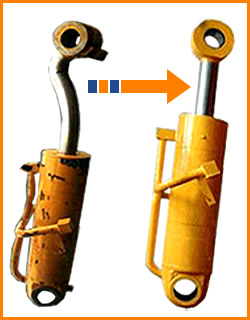

Before & After the Repair Process

This example demonstrates a badly damaged hydraulic ram, before and after. You will see how the cylinder was badly smashed and the end was corroded. We replaced the cylinder and made up a new end before fitting back together and fitted new seals and pressure testing. Use the arrows to switch between images.

JCB 310 Repaired in 24 Hours

Applications of Hydraulic Ram Repairs include:-

- Excavators

- Crushing equipment

- Agricultural machinery

- Forestry machines

- Forklift trucks

- Loaders

- Trenchers

- Waste Management Trucks

- Industrial machinery

- Process machinery

- Grabs

- and many more

All our hydraulic ram repairs go through a quality check and pressure testing before being released back to the customer.

We can inspect your hydraulic system and repair even the most badly damaged hydraulic rams.

Our hydraulic ram repair procedure is as follows:-

-

Cylinder is disassembled

-

Barrel inspected

-

Barrel re-honed or replaced as necessary

-

Rod inspected

-

Rod repaired or replaced as necessary

-

All parts cleaned

-

Seals replaced

-

All threaded connection inspected

-

Cylinder is reassembled

-

Test cylinder to 100% rated pressure along entire stroke